A professional steam path audit can significantly reduce your overall cost

Let a Macek Power steam path audit identify potential part repairs or replacements and help you decide whether these activities are unnecessary or will save you money.

Steam Path Audits

Efficiency loss inside the steam turbine casing can be attributed to two primary causes: leakage and surface roughness. Leakage refers to seals that are worn and/or have excessive clearance. Increased steam path surface roughness can be caused by deposits, erosion, and object impact.

Macek Power steam path audits evaluate steam path components for structural integrity and efficiency loss, then recommend an optimum course of action to take while the unit is open.

Options include:

- Accept “as is”

- Repair

- Refurbish

- Scrap and replace

Factors such as cost, available time, reliability, and efficiency improvement potential influence decisions. Our engineering team considers all of these variables when recommending your best course of action. Your audit will include detailed calculations and computer modeling to provide accurate benefit-cost ratios.

As an example, consider a relatively small 20-MW generator drive that exports energy to the local grid. While serving as owner’s engineer, Macek Power performed a steam path audit during a scheduled major maintenance inspection. Our visual inspection revealed worn seals (large clearances), which we confirmed using “as found” clearance data. Our client had a complete set of replacement seals in storage but was hesitant to install them because the replacement cost would have been approximately US$31,000.

Using techniques similar to those employed for steam turbine rerates, Macek Power determined that new seals could increase turbine mechanical efficiency by 1.4%, which equated to 360 kW (holding all other factors constant). This improvement translated to $158,000 per year in additional revenue due to an increase in electrical energy sales. Thus, the client made the easy decision to replace the seals.

Example Projects

The steam turbine stator vanes shown here were damaged by erosion and object impact, causing the trailing edge material to separate from the vanes. Our steam path audit helped the owner make the most appropriate decision regarding repair or refurbishment. The maintenance service provider offered the owner various repair options: major vane refurbishment via welded reconstruction of the trailing edge, minor rejuvenation with localized weld repairs, and simple polishing. Macek Power used its calculated benefit-cost ratios to guide the owner toward the best decision in regard to the potential for increased efficiency and its conflict with the combined cost of repair activities and extended time offline required to complete those activities

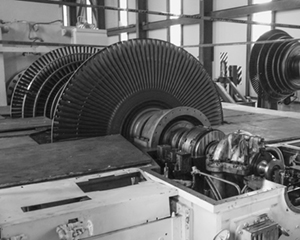

Geothermal units such as the 55-MW double-flow unit shown here typically run on saturated steam high in mineral content, a combination unfriendly to the steam path materials of construction. A Macek Power turbine steam path audit can identify erosion, corrosion, and stress corrosion caused by the use of geothermal steam and help you plan for the inevitable refurbishment or replacement of components.

Steam turbine seal condition can significantly impact efficiency, which, in turn, substantially affects operating cost and/or energy sales revenue. Fuel cost associated with two years of turbine operation can often exceed the capital cost of the turbine itself. Efficiency losses as little as 1% can quickly erode your profit margin. We will use analytical and computer simulation-based methods during the turbine steam path audit to determine your increased operating cost associated with worn or damaged seals.

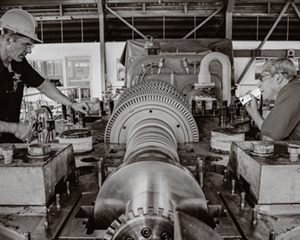

Modern steam turbines with ratings less than approximately 40 MW, such as the one shown here, are usually geared, high-speed, high-energy-density designs. Consequently, running clearances, assembly tolerances, and steam path condition are more critical to reliable operation than larger, low-speed steam turbines. The Macek Power engineering team carefully considers such factors when inspecting these types of turbines.